PRODUCT

When you use the Ansys Connect product suite, you can create a Digital Thread that connects various simulation tools, CAD design, requirements databases, system architecture models, and other information within the Product Life Cycle Ecosystem.

An engineer can create and automate multi-tool workflows, optimize product design, and connect requirements to engineering to enable Model-Based Systems Engineering (MBSE).

It enhances engineering productivity by seamlessly integrating with products from other suppliers that are compatible with all simulation workflows. It's an enterprise-grade simulation process and data management solution with an intuitive and user-friendly user interface.

It allows integration with third-party products, enabling process integration with them as well. You can achieve cost and performance benefits through optimal product design alternatives. It's a comprehensive solution for enterprise-wide process integration and design optimization.

The Enterprise package provides comprehensive materials information management that allows for storage, control, and analysis.

The Pro package offers a fast-start materials information management solution for design and simulation purposes.

It helps find the most suitable materials for various applications. It's an intelligent material selection tool that combines powerful software tools with extensive property data.

The Framework of Model Based Engineering

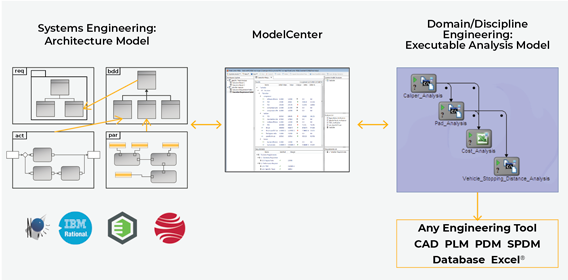

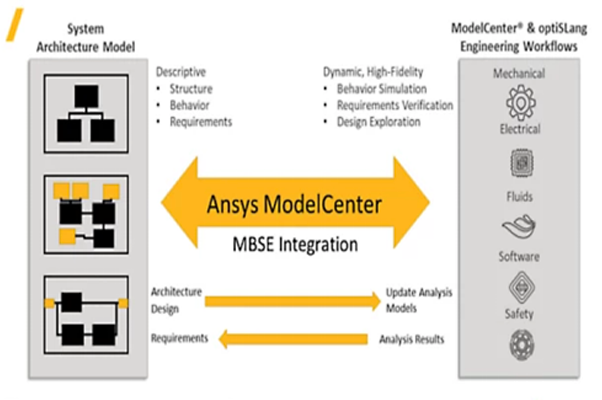

This software platform is designed for creating multi-tool workflows, automating processes, optimizing product design, and enabling Model Based Systems Engineering (MBSE). It not only reduces development costs and increases engineering efficiency but also enhances product competitiveness.

Key Features | ||

Connect Your MBSE Systems Architecture Model SAM) to Any Engineering AnalysisModelCenter provides a graphical user interface for executing the connected ModelCenter workflow. Analysis results can check requirements conformance, with unsatisfied requirements are automatically highlighted. Trade studies can evaluate different design configurations and optimize the system design. New design configurations can update the systems model. | Simulate Complex System BehaviorsModelCenter permits engineers to connect any analysis to behavioral diagrams created using NoMagic MagicDraw/Cameo or PTC Windchill Modeler. The integrated model (behavioral diagram plus analysis) results in a high-fidelity system simulation allowing engineers to accurately VERIFY system behavior and performance early in the design cycle, reducing costs and designing better products. | Automate the Execution of Any Modeling and Simulation ToolModelCenter Integrate provides users with tools and methods that allow them to automate the execution of any modeling tool. Examples include user-created tools and scripts, legacy FORTRAN/C++ programs, spreadsheets, mathematical models, databases, and Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) models. |

Author Engineering WorkflowsOnce a few software tools are automated, ModelCenter’s drag-and-drop graphical user interface can be Once a few software tools are automated, ModelCenter's drag-and-drop graphical user interface can assemble these tools into a complete engineering workflow. An engineering workflow is a flowchart that specifies the order and conditions on how and when to automate the tools. Like flowcharts, workflows can contain branches, if-then statements, loops, etc. Execute the workflow – automatically. ModelCenter's Link Editor allows you to specify the data transferred from one tool to the next when the workflow happens. Your workflow may contain tools that run on any number of different computers and operating systems. | Explore the Design Space and Gain Insight into the Desing ProblemAnalysis and trade-study results can discover significant trends and tradeoffs. Once a repeatable engineering analysis process is created, engineers can repeatedly execute the process (using parallel computing resources if available). Each execution corresponds to a different set of inputs. This process allows engineers to explore and quantify the performance, cost, reliability, and risk of many various design alternatives in a relatively short time. | |

Simulation process and data management (SPDM) made easy.

This is an intuitive integrated platform for simulation processes and data management, process integration and design optimization, and handling large-scale data management tasks.

Key Features | ||

Data ManagementAny Minerva provides state-of-the-art data management to streamline the CAE user experience, enabling you to search, visualize and reuse important data across your organization | HPC Job SubmissionAnsys Minerva offers automatic data collection and hybrid deployment possibilities to make job easier. | Enterprise IntegrationAnsys Minerva’s architecture is vendor-neutral for maximum compatibility and interoperability |

Process ManagementIt takes teamwork to bring exceptional products to market. With Ansys Minerva simulation analysts and project manager can easily assign, own and perform end-to-end process management for staying organized, making better decisions and avoiding unnecessary administrative tasks, saving you valuable engineering time. | Dashboards & ReportMake informed decisions by easily and hybrid deployment possibilities to make jobs easier. | Enterprise DeploymentScale simulation to the entire enterprise by closing the simulation expertise gap |

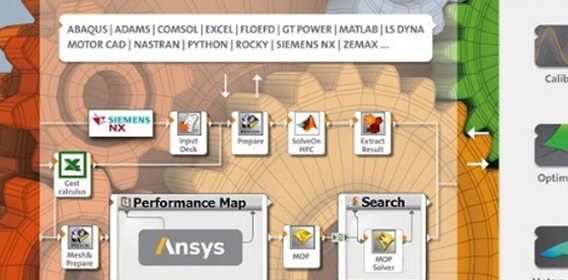

A software platform for CAE-based sensitivity analysis, multi-field optimization, and robustness evaluation across various domains

Key Features | ||

Orchestrate and AutomateAccelerate innovation by minimizing non-value added, repetitive tasks by fully automating and orchestrating the simulation workflows between heterogenous CAX tools across the entire enterprise | Understand and optimize- Reduced Order Modeling- Ansys optiSLang builds metamodels for rapid feedback and robust design analysis in a fraction of the time it would take to run a simulation to predict a certain design. - Design Optimization and Parameter Identification-Ansys optiSLang’s powerful algorithms and automated workflows build on earlier steps of sensitivity analysis to provide a wizard-driven decision tree to recommend the optimizer with default settings | Ansys Minerva IntegrationOne of the major challenges of today’s CAE engineers is the increasing complexity of processes while results have to be delivered in shorter times. At the same time, within the engineering process, multiple disciplines like NVH, thermal-mechanical-electrical analyses, safety evaluation, tolerance management and costs have to be considered. Improving one discipline could require a compromise in others. |

Industry-leading Materials Intelligence

The entire company can make more rapid decisions and develop better products more quickly by utilizing consistent and traceable material information.

Key Features | ||

Additive ManufacturingOptimize your additive manufacturing data and project knowledge. Utilize insights to get your additive solutions to market faster, and improve your understanding of critical process and property relationships. Integrating easy-to-use Machine Learning applications into Granta MI to reduce trial and error in additive manufacturing. | Minimize Restricted Substances RisckWe combine best practices to help minimize restricted substances risk through practical analytics, reporting and decision-making tools. Offering an unrivalled, regularly updated library of references data to keep your teams up to date with evolving regulations. | Comprehensive Materials DataOur extensive array of interlinked materials data includes our comprehensive and comparable MaterialUniverse™ dataset with technical, economic and environmental information for thousands of engineering materials. Additional detailed information is available on metals, polymers, composites, coatings, electromagnetic materials, medical materials, aerospace materials - including design data, manufacturer's datasheets, standards-based information and test data. |

Test Data ManagementUtilize efficient, traceable materials testing and analysis process – from test lab to design data – to maximize your return on investment. | Integrate Seamlessly with CAD, CAE andPLM SystemsGranta MI Enterprise is fully embedded with leading systems – CAD, CAE and PLM – to ensure accurate application of materials data and properties. | Boosting Simulation AccuracyImprove simulation accuracy with access to an unrivalled catalog of materials property data. |

Material Information Control Software

This is a solution for individual users and teams in the field of design and simulation.

Key Features | ||

Build Lists of Preferred MaterialsBuild on the basic materials dataset to create your own list of preferred materials with the right properties you need for simulation. | Store Data SecurelyPersonalize your materials database and then ensure its security with Granta MI Pro | Import from Ansys Granta SelectorQuickly and easily import materials data you’ve down selected using Granta Selector to add to your company’s materials dataset. |

Integration with Creo®, NX™, HyperMesh™ and Ansys WorkbenchGranta MI Pro is rapidly accessible from a growing list of CAD and CAE providers – allowing immediate access to your trusted materials data. | Export to SOLIDWORKS®Export directly to SOLIDWORKS® to simply assign your materials data to your design. | |

Choosing Smarter Materials

When using Granta Selector, you can innovate and address material issues, reduce costs, and validate material choices.

Key Features | ||

Intelligent Material SelectionEnsure exhaustive, repeatable and auditable materials selection. Find similar materials to current choices or explore the entire available materials space. Rapidly compare material choices and balance competing performance requirements. Part Cost EstimationEstimate manufacturing costs at the conceptual design phase. Account for materials, manufacturing method and batch size. | Comprehensive Materials DataOur extensive array of interlinked materials data includes our comprehensive and comparable MaterialUniverse™ dataset with technical, economic and environmental information for thousands of engineering materials. Additional detailed information is available on metals, polymers, composites, coatings, electromagnetic materials, medical materials, aerospace materials - including design data, manufacturer's datasheets, standards-based information and test data. | FE Export and Ansys Workbench IntegrationSeamlessly feed simulation-ready engineering data into Ansys Workbench as part of an integrated workflow. Export data to Ansys Discovery, Ansys Granta MI Pro or a variety of third-party CAD/CAE software solutions. Eco Design AuditStraightforward evaluation of the environmental impact of your product and its component. Identify key areas to focus on, and provide guidance on how to reduce embodied energy and Co2 footprint at all stages of the product lifecycle. |

Create Hybrid MaterialsPredict the performance and properties of hybrid materials and structures and compare them with standard materials. Comes with several built-in models and structures, or create your own. Or, predict the key properties and performance of several multi-cell battery module configurations and carry out equivalent comparisons between them. | Selector for Research and AcademiaCompare your in-house experimental research data with built-in comprehensive materials data. Synthesize hybrid materials and assess their properties. Data visualization and analysis tools to guide through the whole research project. Support advanced educational reports and all kinds of publications. | |